Beschreibung

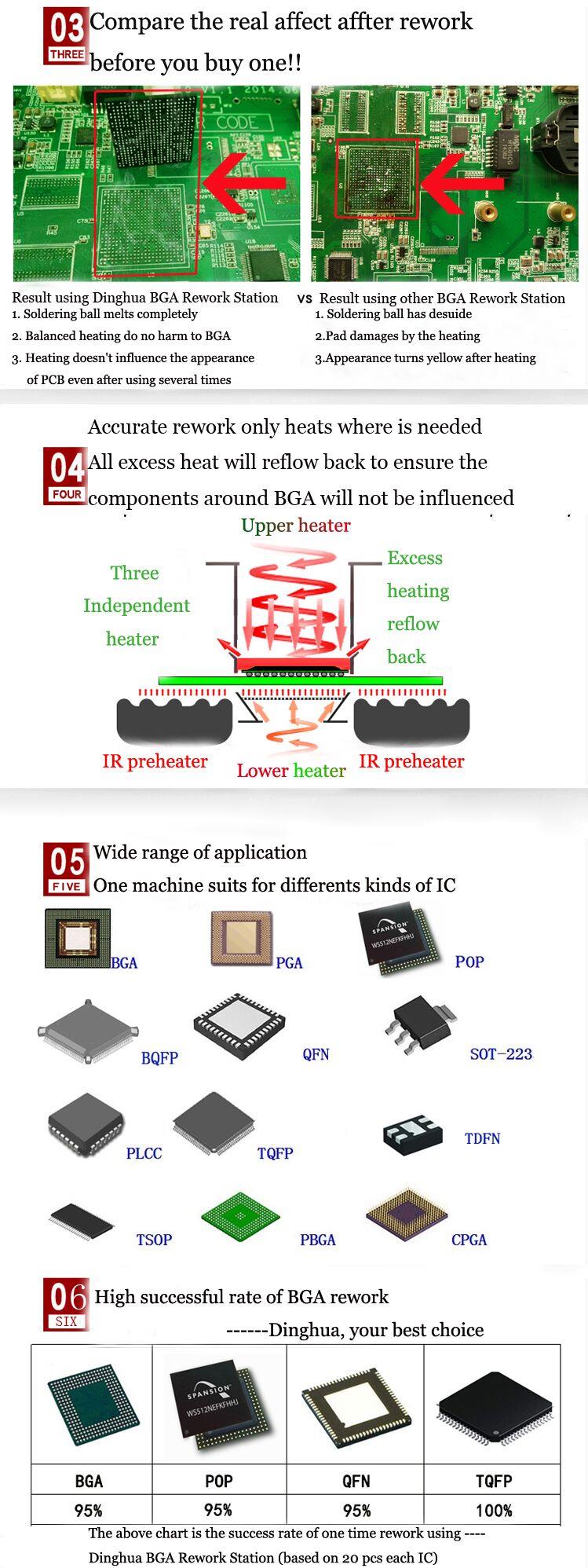

1.Application Of Hot Air

Solder, reball, desoldering different kind of chips: BGA,PGA,POP,BQFP,QFN,SOT223,PLCC,TQFP,TDFN,TSOP, PBGA,CPGA,LED chip.

2.Product Features

3.Specification of laser positioning

| 5300W | |

| Hot air 1200W | |

| Hot air 1200W.Infrared 2700W | |

| AC220V±10% 50/60Hz | |

| L530*W670*H790 mm | |

| V-groove PCB support, and with external universal fixture | |

| ±2 degree | |

| Max 450*490 mm,Min 22*22 mm | |

| Workbench fine-tuning | ±15mm forward/backward,±15mm right/left |

| 80*80-1*1mm | |

| 0.15mm | |

| 1(optional) | |

| 70kg |

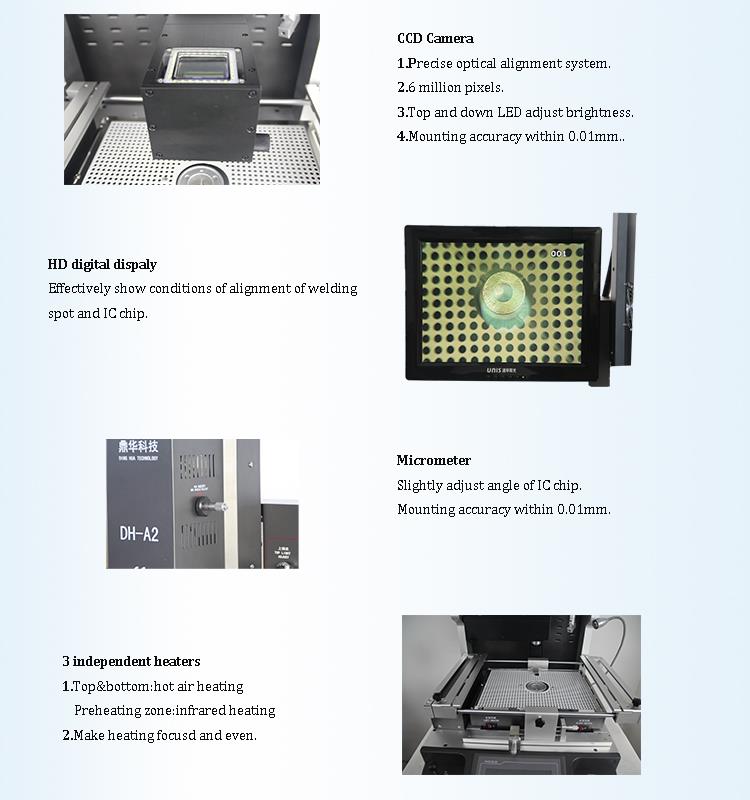

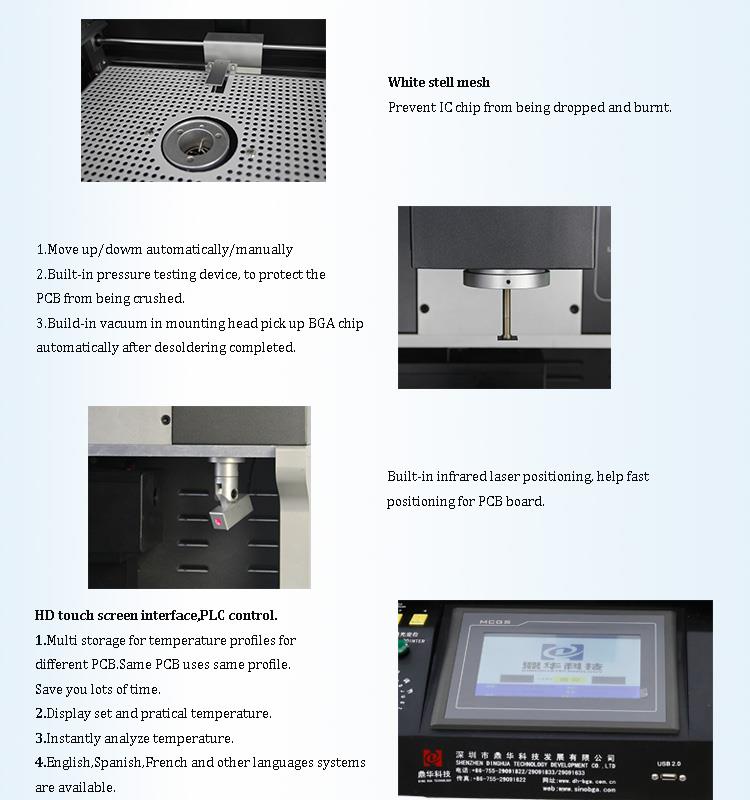

4.Details of Infrared BGA Remover Automatic

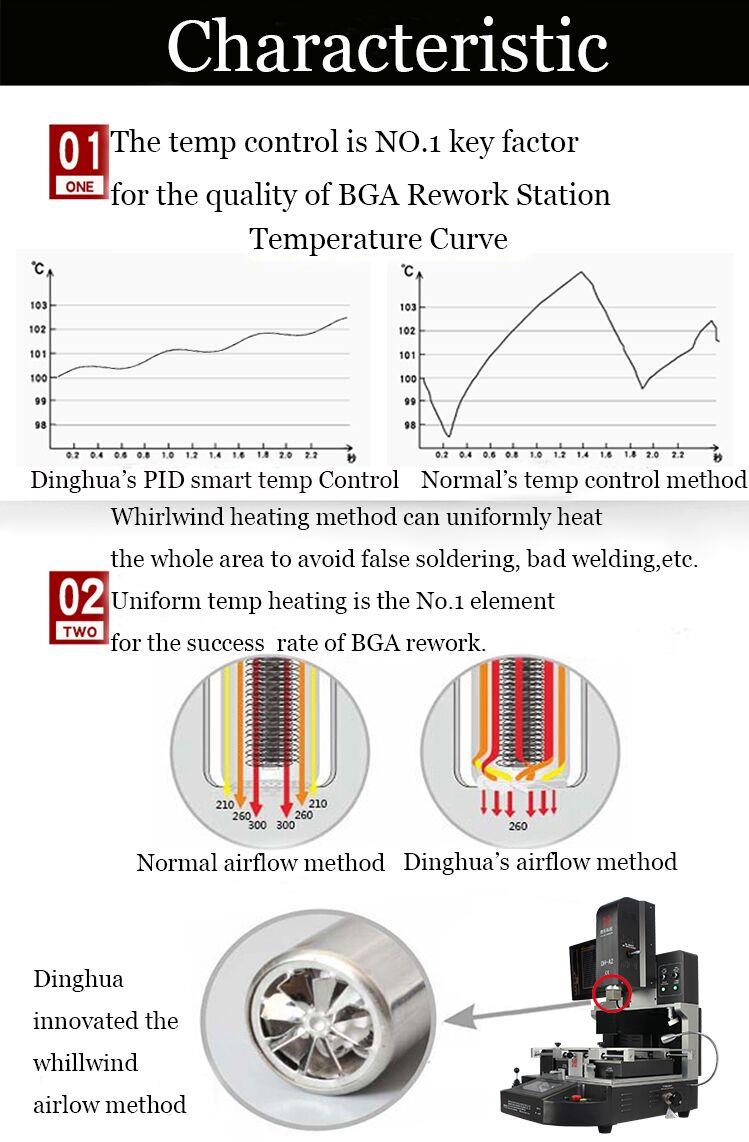

5.Why Choose Our Infrared BGA Remover Automatic?

6.Certificate of Optical Alignment

UL, E-MARK, CCC, FCC, CE ROHS certificates. Meanwhile, to improve and perfect the quality system, Dinghua has passed ISO, GMP, FCCA, C-TPAT on-site audit certification.

7.Packing & Shipment of CCD Camera

8.Shipment for

9. Related knowledge

The tube is one of the earliest components used for amplifying electrical signals. It consists of a cathode electron-emitting portion, a control grid, an acceleration grid, and an anode (screen) lead, all enclosed in a glass container (generally a glass tube) that is welded to the tube base. An electric field is employed to inject an electronic modulation signal into the control grid within the vacuum, resulting in different parameter signal data after signal amplification or feedback oscillation is obtained at the anode.

While early applications in electronic products such as televisions and radio amplifiers have gradually been replaced by amplifiers and integrated circuits made of semiconductor materials in recent years, tubes with low noise and high stability are still used as audio power amplifier components in some high-fidelity audio equipment. In Hong Kong, people refer to tube power amplifiers as "amplifiers."

To maintain the vacuum inside the tube, a component called a deaerator is placed within the vacuum tube. It is typically made from a live metal alloy such as bismuth, aluminum, or magnesium. After the air in the tube is evacuated, the components inside the tube and the deaerator are heated to a red heat so that any gas contained in the electrodes can be absorbed. The deaerator is rapidly sublimated by a high-frequency electromagnetic field surrounding the tube, allowing it to absorb the gas in the tube. After this reaction, a silver coating from the deaerator accumulates on the inner wall of the glass tube. If the glass tube is broken or leaks, the silver coating will fade, indicating that the vacuum tube can no longer be used.